Our Store Pages

Bending

|

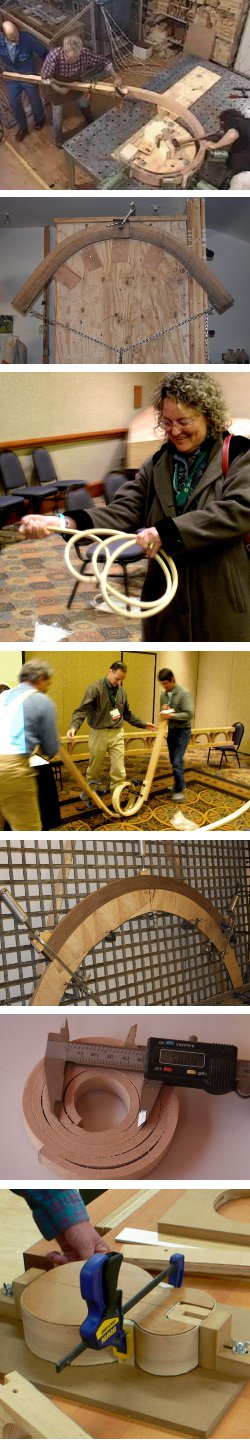

Bending Cold-Bend™ hardwood Cold-Bend™ hardwood is a Superwood that can bend because it can stretch out as it is bent. It'll bend in any direction, and twist too. Don't make your first experiece with Cold-Bend™ hardwood a paid project for a customer. There is a learning curve. Get to know what tools you want to have around, how to use leverage to accomplish the bend, how the wood will look after it is bent and dried, and how you willl surface it to fit other components. You need to learn how to avoid or control shrinkage and cupping, what tools will put unwanted marks in the wood and how best to support the wood during bending and drying. The first thing you could do with Cold-Bend™ hardwood is to re-saw a piece to about 3/8" to 1/2" square, and bend it into a ring. Tie it in a knot, then keep reducing the radius to about 1:5, which means a 1" thick board can be bent to a 5" radius, a 1/2" thick board can be bent to a 2.5" radius and so on. Coarse grained hardwoods like Ash and Oaks can frequently be bent further, beyond the recommend 1:5, thickness:radius ratio. It is Ok to bend further. If a failure shows up due to over-bending, it will show up in the initial bending, not later during drying. Most people are not aggressive in testing the bend radius. If you are trying to bend a thick piece, and it seems to resist being bent as far as you think it should go, if you haven't broken it, you probably just didn't have enough leverage on it, and haven't made it to the limit of how far it can bend. Once you have a tight knot, weave or wrap the remainder of the strip around the ring you've created, sort of like you are creating a wreath. You should break a small piece just to see how far it can go. If you haven't broken a test strip, you haven't seen how far it can go yet. Below are some general recommendations for working with Cold-Bend™ hardwood.... It is best to have surfaced (sanded) the compressed wood before bending because it is easier to sand the flat, unbent parts. You do not have to account for spring back in Cold-Bend™ hardwood. It holds its shape on the form as long as it is fixed in shape by proper drying on the form. Cold-Bend™ hardwood may be easily cold bent by hand for thinner dimensions, or by using mechanical leverage for thicker dimensions. Bend the wood on a form that supports the complete inside of the curve to get precise shapes. Multiple and complex curves, and twists, may be produced within the same part, but some consideration needs to be made to fixture the part. For sculptural pieces where precision is not required, the fixtures can be fairly simple. Compressed wood takes a "set", or "memory" of its shape within a few minutes, but the longer the set, the better the memory, so give it about 30 minutes. You can over-bend and use shorter hold times too. Compressed Wood is not meant for very gentle bends, unless you have full support during drying. The wood wants to bend, so if you are aiming for a gentle bend, it is tricky to keep it from moving during drying. There is no need to support the outside curve on the part, but if you need absolute precission in size, and don't plan to surface very much after drying, do also secure the outside curves well, and use clamping cauls to even out the clamping pressue so that the wood is supported fully and evenly. For difficult curves or small radius curves, pneumatic and hydraulic presses may be employed, but hand clamps may be used for almost any bend you can think of. A favorite clamp for bending and holding the bent shapes is the Irwin XP500 (the XP is blue and silver, not the cheaper yellow and blue Irwin). It grabs on to odd angles unlike anything else and has quite a bit of strength. Ratchet straps are quite usefull too. A bend target of 5 times the board thickness is a minimum radius target for extreme bends in most species (coarse grained woods) (fine grained woods 1:6), but various techniques can be employed to exceed this. For instance, a 1/2" board can usually be bent to a 2.5 inch radius, and a 1" thick part can potentially be bent to a 5" radius, and so on. Hand bending is a great way to use Compressed Wood. The middle of long strips bend easier than the ends, but only because you have more leverage on it. It's just harder to get good leverage at the end, but you can use the ends efficiently if you can get some leverage on it. This applies more to 1" and thicker parts. Under 1/2", it's pretty easy to bend almost all the way out to the ends. Plan on a few inches of waste at the end so that you can trim it later. Also plan for a little shrinkage during drying (about 0.5%). The wood does not need to be, and should not be heated or steamed prior to bending. Steaming compressed wood actually takes the compression out of it. It bends to extreme radii at room temperature. As long as it hasn't dried, it will bend. As the wood ages and dries, it will be less pliable. Rewrap your unused compressed wood in kitchen stretch wrap after resawing to retain the moisture and flexibility of the remaining wood. If you have a piece that has dried out on your work bench or shop floor, you can make it somewhat flexible again by soaking in warm water (if it hasn't already been kiln dried), or for small pieces, a short time in a microwave to warm it. Give it just enough time in the microwave to warm it, not so much that you dry it out. When putting wood in a microwave, it'll dry the inside first where you might not notice it, and if you keep drying this way, you can turn the inside of the wood into charcoal, and it will smoke, and I suppose going far enough would lead to fire. |

|

Loading... Please wait...

Loading... Please wait...